If there is a difference in electrical potential between one conductive surface and another, then an electromotive force exists. If you touch both, that EMF travels through you – with potentially damaging effects. Potential electrical discharges can also damage equipment or start a fire. Engineers that work in plumbing and for Gloucester Boiler Service companies such as http://www.hprservicesltd.com/gloucester-boilers/boiler-service-gloucester/ take many safety precautions to ensure that they are working in a safe environment and that where necessary the electrical supply to a particular appliance such as a boiler or particular area of the house is switched off before work begins.

Electrical Bonding

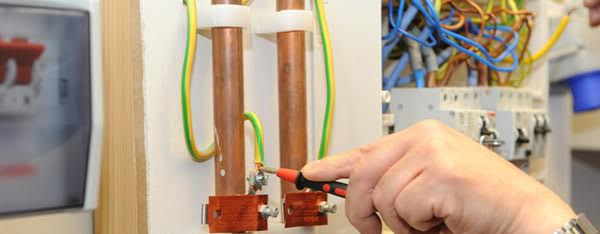

Electrical bonding and earthing are both ways to address this danger. Bonding is the strategy of connecting components or surfaces together with a conductor so that no potential difference can arise between them. Earthing denotes the connection of the whole system to earth so charge can then drain away. It’s often used synonymously with “grounding”, although technically grounding can denote the neural pathway that returns current to the source. Wherever possible, Earth connections use green (or yellow and green) cabling, whereas in the technical sense grounding is often accomplished by a black one (never assume either is safe to touch when an appliance is connected).

Even the charge from an AA battery can damage electronics if it discharges incorrectly, although the current is not a direct threat to health. However, a shock from a car battery can be enough to kill. Any equipment for connection to the mains must be safely earthed. Bonding and earth connections are usually secured with metal grub screws, bolts, soldering or welding.

Metal Bonding Adhesive

Most adhesives are insulators, but their use to create electrical connections is becoming more common due to the development of new conductive adhesives. These usually take the form of adhesive resins and pastes infused with conducting materials like silver or carbon fibers. Whilst these are already being successfully used in low voltage electronic circuits, metal bonding adhesive does not normally have the combination of conductivity and adhesive reliability to replace metal joints for safety-critical earthing, although they can add strength to them.

However whenever electricity is involved always be clear whether conductance or insulation is the quality you require and consult the supplier for advice. It is also common sense to use registered electricians for electrical repairs and household wiring.

Conductive adhesives are sometimes painted on the inner surface of insulating boxes. So used, they create a Faraday cage that contains electromagnetic radiation and inhibits discharges between internal and external components.